3D PRINTING MATERIALS

Fused deposition modeling - FDM

FDM - Fused Deposition Modeling

Fused deposition modeling (FDM) additive manufacturing technology

3D printers based on FDM technology manufacture parts layer by layer by heating the thermoplastic material to a semi-liquid state and extruding it in accordance with the computer controlled course.

For manufacture, FDM technology uses two materials : a modeling material , which constitutes the finished piece , and a support material, in lieu of reinforcement.

The filaments of material are sent from a reel towards the print head , which moves along X and Y coordinates , depositing the material to achieve each layer before the base from moving downward along the Z axis and that the next layer begins.

When the 3D printer has realized the manufacture , the user detaches the carrier material or dissolved in detergent and water. The part is then ready for use .

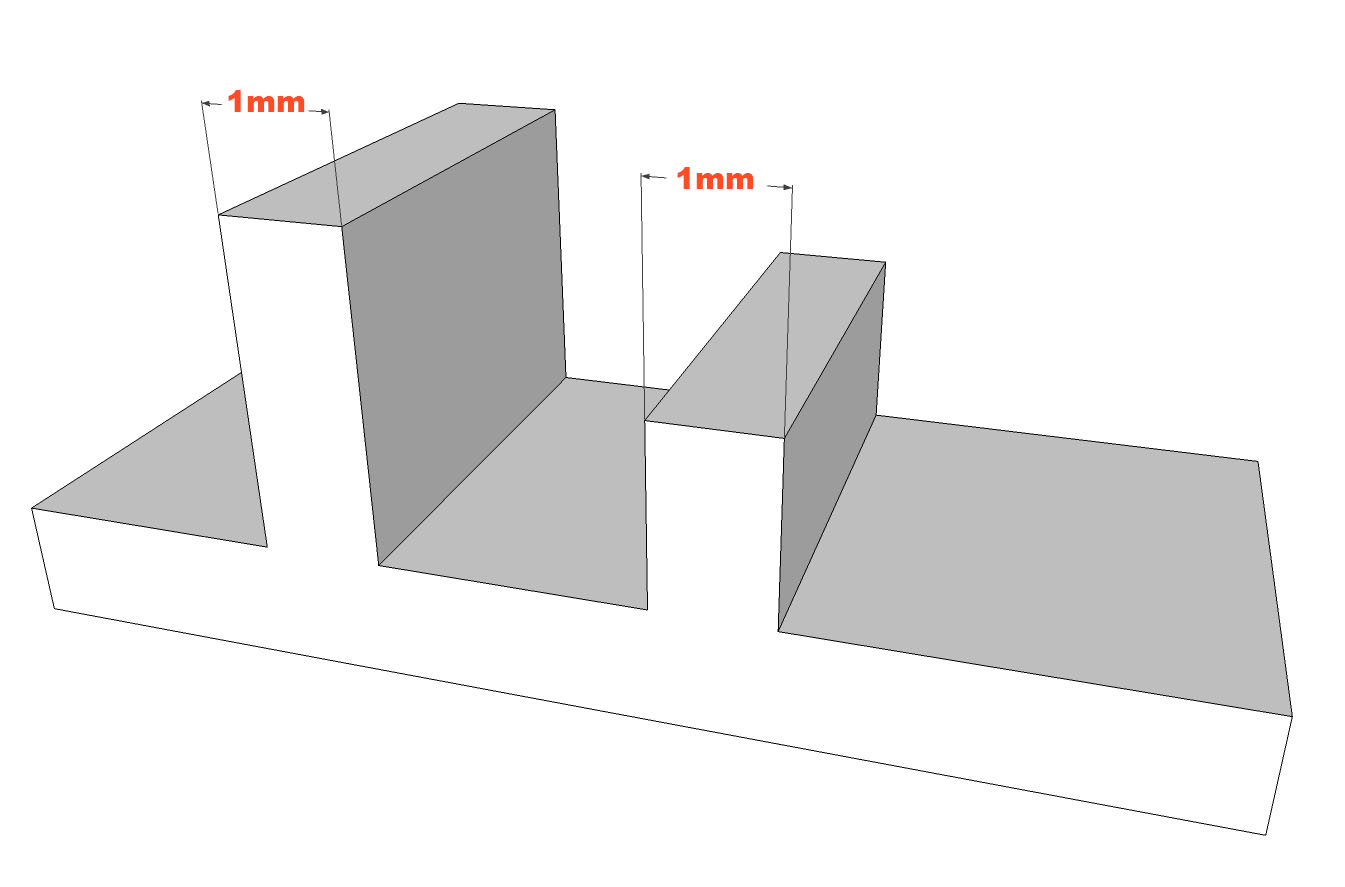

Thickness minimum of walls

Minimum wall thickness for assembled walls: 1mm

Materials in FDM

Material ABS:

Examples of areas of application:

The strength of the ABS material is 80% similar to that of an injection cast ABS, so it is suitable for functional applications.

Characteristics:

Appearance of stratifications.

Advantages:

Reliable and robust functional prototypes.

Material ABS-PC (polycarbonate):

Technical and robust thermoplastic.

Examples of application:

Used for functional prototyping, tools which requires excellent shock resistance.

Characteristics:

This material has the features of two excellent FDM thermoplastics: the robustness and heat resistance of the PC and the flexibility of the ABS.

Advantages:

Reliable and robust functional prototypes.

Material Ultem Black:

Allows to print parts with thermal properties.

Examples of application:

This material is ideal for aerospace, automotive and military applications due to high strength/weight ratio and certifications.

Characteristics:

This material has complete thermal, mechanical and chemical properties.

Advantages:

Functional prototypes.

FRA

FRA ESP

ESP ENG

ENG